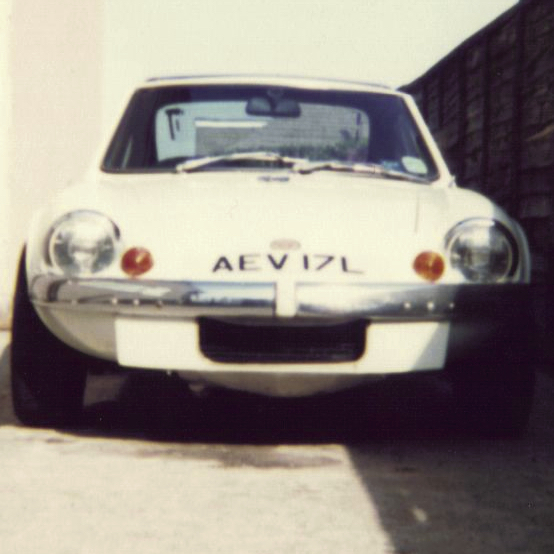

Ginetta G15

Continuing the story of my Ginetta G15 ownership, with the engine very poorly, the car was towed home by my Dad’s Vauxhall Viva (this car being a dark Blue colour). With a very lightweight sports car being towed & for the first time in my driving history, it was a pretty traumatic journey. We got home & immediately the car was jacked up onto 4 wheel ramps. Who even does this these days with their car? The mechanical noise was still there when the engine was turned over. It was quickly apparent that the fault was not the exhaust or the carburettors.

We decided to remove the sump & have a look at the crankshaft turning over. It was possible to manually turn the crank & once again there didn’t seem to be anything wrong. At this point our next door neighbour turned up to have a look see. This kind gentleman would always be the first to offer his help & his extensive collection of tools collated over many years. Being quite new to stripping engines down at this point in my motoring history, we began turning the engine over again, with our neighbour intently looking up at the exposed bottom end of the Hillman Imp internals, with his pocket torch. We reversed the rotation very slightly & then we could see the problem, all three of us at once! A crack right across the crankshaft between 2 of the balancing webs. So the engine had carried on rotating, albeit very roughly with a massive crack, effectively resulting in 2 independent crankshafts rotating very slightly out of synchronisation with each other. There was obviously other metal to metal contact.

What followed was a rebuild by myself using a new 998 cc short block engine from Talbot Spares. In those days it was pretty easy to obtain the necessary spares for the Hillman Imp, including racing parts. My first foray into engine building was lots of fun. I did have one cylinder block engine stud that sheared, which was quickly removed using my neighbour’s stud remover kit. There was contact with the piston heads & valves so a new set of valves & springs were fitted. This necessitated setting the valve clearance’s & timing the camshaft. All very technical stuff but very enlightening & great experience for future engine builds.

My Ginetta G15 stayed engine-less for a couple of days as shown in the photo below. You can see that this car was well used in all weathers & I did like to use my wax-oil spray on the chassis!

When re-fitting the engine & transaxle back to the chassis, the rubber couplings had to be re-fitted between the outboard drive shaft & the inboard transaxle shaft. Now let me tell you this is an almost impossible job, especially when using competition doughnuts (rubber couplings), which have almost zero flex. Once fitted its a great design & works exceptionally well, its just that the designer didn’t leave a great deal of clearance for the actual re-fitting of these couplings. I can look back with fond memories of fitting these couplings maybe 8 – 10 times with my ownership of the Ginetta G15 & later Hillman Imp & Sunbeam Stiletto.

With the car back as it was prior to the crankshaft failure the engine started first time & just needed the carburettors setting up. One quickly became an expert at listening to the hiss from each of the 4 carburettor bell-mouth inlet pipes – to produce as close to a consistent as possible ‘hiss sound’ from each inlet pipe. Instead of “Rack of the Eye” – this was “Rack of the Ear!” The car was completely well again & continued to be a massive pleasure to drive.